About

Innovative Life Science Manufacturer for Over 30 Years

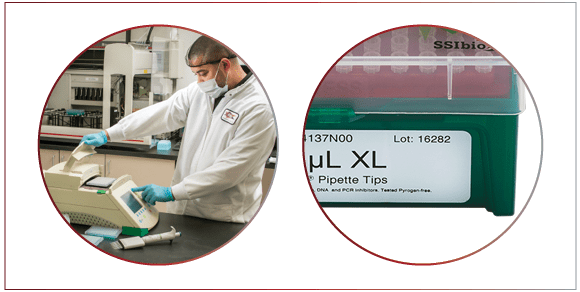

Since 1990, Scientific Specialties has focused on bringing innovative, high-quality plasticware to life science. Our founder and CEO is a Ph.D. Biochemist who understands the specific needs and challenges of laboratory research and incorporates that knowledge into products that make your work easier and more successful.

Because of our commitment to innovation and quality, laboratories around the world have come to rely on our plastic consumables for everyday research as well as ground-breaking discoveries.

Want to become apart of the SSIbio Team?

An Experienced and Capable Manufacturing Partner You Can Trust

Made in USA

Every Product is proudly maufacturerd in the USA.

Purity Assured

Products are Certified free of detectable RNase, DNase, DNA, PCR inhibitors, and endotoxins (pyrogens).

Recyclable

Product is fully compliant with recycling standards.

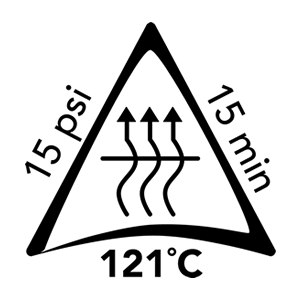

Autoclavable

Where specified, products may be steralized at 121C and 15 psi for 15 minutes.

Competence

Our processes are controlled under a certified ISO-9001:2015 quality assurance system. From the initial concept of a product to its finished form, we control all aspects of the design, production and quality in our state-of-the-art manufacturing facility, located in Lodi, California. We are one of the few producers of laboratory plastics still manufacturing in the USA—an important distinction between SSIbio and other brands.

Excellence

All products are manufactured in our 11,300 square-meter (122,000 square-foot) facility. This includes 3,700 square meters of dedicated clean, climate-controlled industrial space—of which, 1,500 square meters meet or exceed ISO 8 / Class 100,000 standards. This ensures that all production and packaging are performed in an environment that meets rigid cleanroom specifications.

Quality injection molding, coupled with the integration of robotics, and our rigorous QA/QC processes demonstrate our commitment to excellence and guarantee product that is uniform, pure, and worthy of your trust.

Partnership

At Scientific Specialties, we know that having a reliable partner is important to our success. That is why we have built a business on also being the right partner to our customers. As a privately-held entity, we are able to make decisions and invest in equipment and other innovations to be more productive and responsive to the needs of our customers.

Innovation

Eight design patents attest to our passion for innovation and are incorporated in daily-use laboratory products that enhance or simplify user experience.

Press-to-Open Rack Lid enables easy one-handed operation.

Triple-Interwell Linkages and Angled Caps revolutionized strip tubes, resulting in less spillage and more research.

Pipette tip grid with lock mechanism facilitates easy reloading of empty racks.

Control

Every production lot is quality tested for physical and chemical compliance to rigorous standards in our well-equipped, state-of-the-art quality assurance laboratory.

All shipments carry the manufacturing lot number so that, in the unlikely event of a problem, the code can be traced back to the exact production date and the very mold that was used to produce the part to ensure no further issues exist.

Purity & Clarity

Our commitment to high-quality plastics has made us a leader in PCR consumables where optical clarity and purity are critical, and is evident in all of our other products as well. You can be assured that every consumable product you purchase from SSIbio will be free of detectable DNase, RNase, DNA, and PCR inhibitors and, for those products which are sterile, we employ E-beam sterilization to eliminate pyrogens and ensure absolute purity.

It all starts with the right resin. At SSIbio, we use high-clarity, ultra-pure polypropylene that meets FDA 21 CFR 177.1520 and USP Class VI.

ISO 8, Class 100,000 Cleanroom Production

All products are manufactured in our 11,300 square-meter (122,000 square-foot) facility. This includes 3,700 square meters of dedicated clean, climate-controlled industrial space—of which, 1,500 square meters will be formally certified to ISO 8 / Class 100,000 standards. This ensures that all production and packaging are performed in an environment that meets rigid cleanroom specifications.

Quality

All products are required to pass rigorous laboratory testing before sale. A Certificate of Conformity and Analysis is available that defines the testing protocols followed. This is your guarantee of quality and satisfaction.

All processes—from design to production and packaging—are controlled under a certified ISO-9001:2015 Quality Assurance system.

The use of automated inline robotics, vacuum testing, and optical inspection identifies and eliminates non-conforming product.

.png)